How to measure the conveying capacity of the Vacuum Feeding Machine?

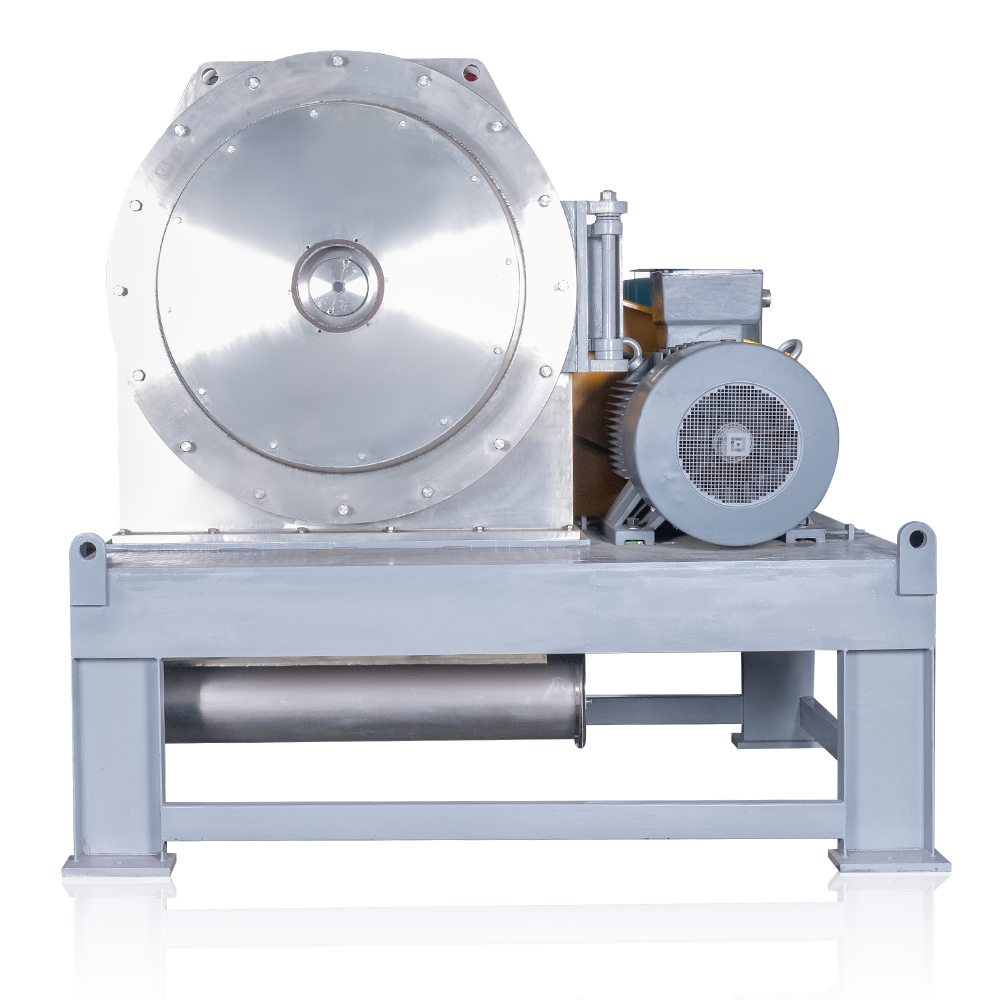

As an automated conveying equipment for powder, granular and mixed materials, the reasonable evaluation of the conveying capacity of Vacuum Feeding Machine is crucial to production efficiency. The measurement of conveying capacity requires a comprehensive analysis of multiple factors such as equipment performance parameters, material characteristics, system design and operating conditions to ensure that the equipment selection matches the production needs.

In the equipment selection stage, different models of Vacuum Feeding Machine have different conveying upper limits, and the material conveying volume per unit time (kg/h or t/h) is usually used as the main reference indicator. The specifications of the equipment directly affect its applicable scenarios, so it is necessary to select a suitable model according to actual production needs. At the same time, the physical and chemical properties of the material have a significant impact on the conveying efficiency, including the density, particle size distribution, fluidity, humidity and electrostatic characteristics of the material.

The design of the conveying system also plays a decisive role in the conveying capacity. The length, diameter and number of bends of the pipeline will affect the airflow resistance and material flow efficiency. Longer conveying distances or too many elbow designs will increase system resistance and reduce conveying efficiency; while appropriately increasing the pipeline diameter will help increase the conveying speed. The operating parameters of the equipment also need to be optimized and adjusted. For example, the vacuum level directly affects the adsorption force, while the consumption of compressed air is closely related to the conveying speed. The continuous feeding mode is usually more efficient than the intermittent mode, but it needs to be selected in combination with specific process requirements.

The performance of the filtration system is crucial to the long-term stable operation of the Vacuum Feeding Machine. The type, accuracy and maintenance frequency of the filter will affect the airflow resistance and system stability. Efficient filtration devices can reduce the risk of material residue and clogging, thereby maintaining a high conveying efficiency and extending the service life of the equipment.

Contact Us

-

Email: [email protected]

-

Telephone: +86-576-87685299

-

Fax: 0575-83505616

-

Phone: +86-17717510892

English

English عربى

عربى 한국어

한국어 中文简体

中文简体