How does the calcium carbonate modification machine achieve particle size control?

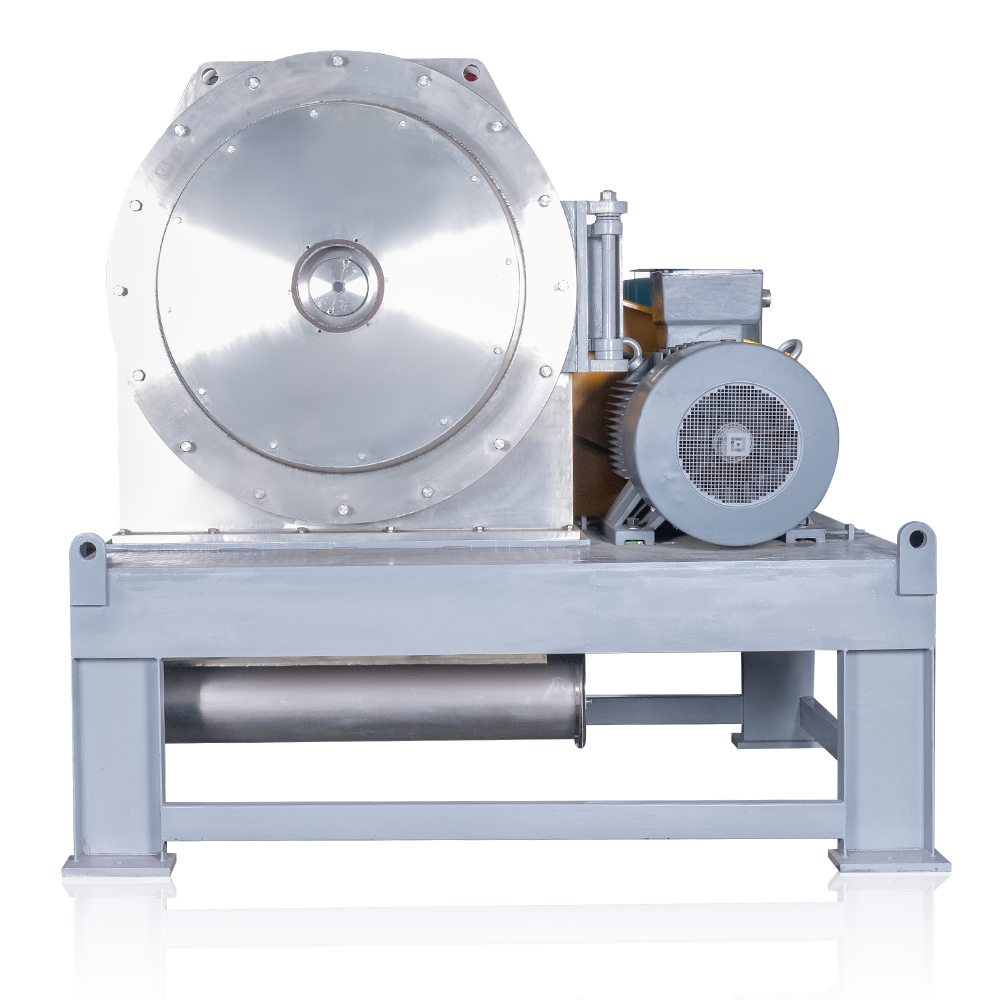

The calcium carbonate modification machine involves a variety of processes and technical means to achieve particle size control, including mechanical grinding, physical adjustment, chemical modification, etc. The following will introduce in detail how the calcium carbonate modification machine achieves particle size control.

First, the calcium carbonate modification machine controls the particle size through mechanical grinding. In the calcium carbonate modification process, mechanical grinding is a common method, which gradually reduces the particles through friction and impact between calcium carbonate particles. Usually, after calcium carbonate particles enter the modification machine, they will be crushed and ground by high-speed rotating grinding devices or grinding media, such as ball mills, sand mills, etc., so that the particle size of the particles gradually decreases.

Secondly, physical adjustment is also one of the important means to achieve particle size control. The calcium carbonate modification machine controls the particle size of calcium carbonate particles by adjusting process parameters, such as stirring speed, grinding time, type and size of grinding media, etc. For example, increasing the stirring speed and grinding time and using fine grinding media can accelerate the grinding process of calcium carbonate particles, thereby reducing the particle size.

In addition, chemical modification can also be used for particle size control. By introducing or changing chemical components, such as surfactants, polymers, etc., on the surface of calcium carbonate particles, the interaction force and surface energy between particles can be changed, thereby affecting the aggregation state and particle size distribution of calcium carbonate particles. Chemical modification can improve the dispersion and stability of particles and reduce the agglomeration and accumulation of particles, thereby achieving control of particle size.

Finally, particle size control can also be achieved through physical methods such as screening and classification. Calcium carbonate-modified particles can be screened and classified through screening equipment to separate particles in different particle size ranges to meet the needs of different industries and applications. In addition, particles can be classified and their size controlled through airflow classification, centrifugal separation and other methods.

The calcium carbonate modification machine realizes the regulation of the particle size of calcium carbonate particles through various means such as mechanical grinding, physical adjustment, chemical modification and physical classification. Reasonable selection and combination of these means can achieve precise control of calcium carbonate particle size and meet the particle size requirements of calcium carbonate products in different industries and applications.

First, the calcium carbonate modification machine controls the particle size through mechanical grinding. In the calcium carbonate modification process, mechanical grinding is a common method, which gradually reduces the particles through friction and impact between calcium carbonate particles. Usually, after calcium carbonate particles enter the modification machine, they will be crushed and ground by high-speed rotating grinding devices or grinding media, such as ball mills, sand mills, etc., so that the particle size of the particles gradually decreases.

Secondly, physical adjustment is also one of the important means to achieve particle size control. The calcium carbonate modification machine controls the particle size of calcium carbonate particles by adjusting process parameters, such as stirring speed, grinding time, type and size of grinding media, etc. For example, increasing the stirring speed and grinding time and using fine grinding media can accelerate the grinding process of calcium carbonate particles, thereby reducing the particle size.

In addition, chemical modification can also be used for particle size control. By introducing or changing chemical components, such as surfactants, polymers, etc., on the surface of calcium carbonate particles, the interaction force and surface energy between particles can be changed, thereby affecting the aggregation state and particle size distribution of calcium carbonate particles. Chemical modification can improve the dispersion and stability of particles and reduce the agglomeration and accumulation of particles, thereby achieving control of particle size.

Finally, particle size control can also be achieved through physical methods such as screening and classification. Calcium carbonate-modified particles can be screened and classified through screening equipment to separate particles in different particle size ranges to meet the needs of different industries and applications. In addition, particles can be classified and their size controlled through airflow classification, centrifugal separation and other methods.

The calcium carbonate modification machine realizes the regulation of the particle size of calcium carbonate particles through various means such as mechanical grinding, physical adjustment, chemical modification and physical classification. Reasonable selection and combination of these means can achieve precise control of calcium carbonate particle size and meet the particle size requirements of calcium carbonate products in different industries and applications.

Contact Us

-

Email: [email protected]

-

Telephone: +86-576-87685299

-

Fax: 0575-83505616

-

Phone: +86-17717510892

English

English عربى

عربى 한국어

한국어 中文简体

中文简体