If you need any help, please feel free to contact us

Product Series

-

- Ultrafine Grinding Equipment

-

- Turbo Ultrafine Classifier

-

- Pre-crushing equipment

-

- Vacuum Feeding Machine

-

- Fusion Coating Machine

-

- Graphite Spheroidization Crushing Equipment

-

- Carbon Black Crushing Equipment

-

- Calcium Carbonate Modification Machine

-

- Nano Calcium Deagglomeration Machine

-

- Carrageenan/Guar Gum Grinding Equipment

Fusion Coating Machine Manufacturers

Information to be updated

Who are we?

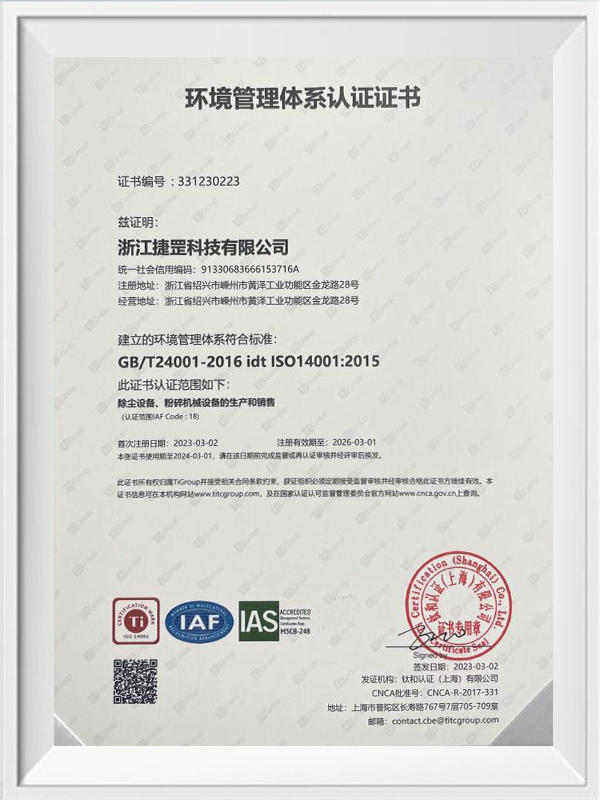

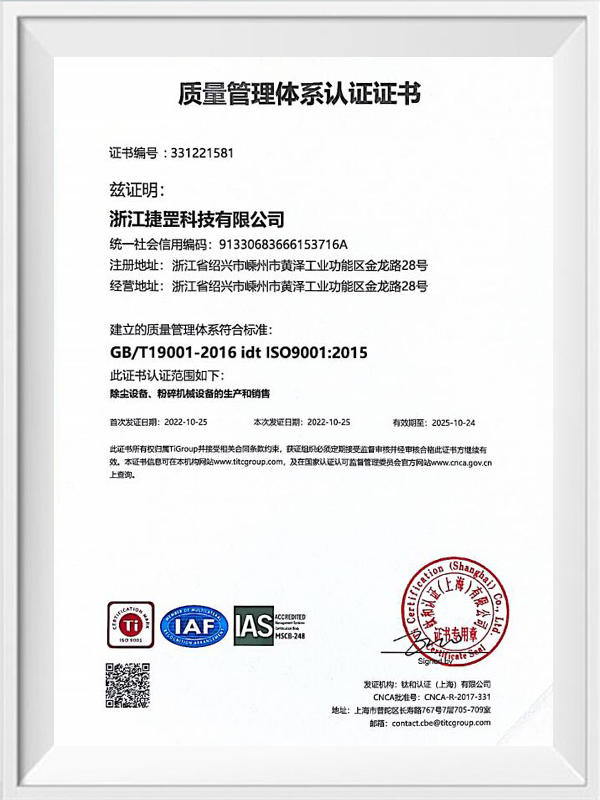

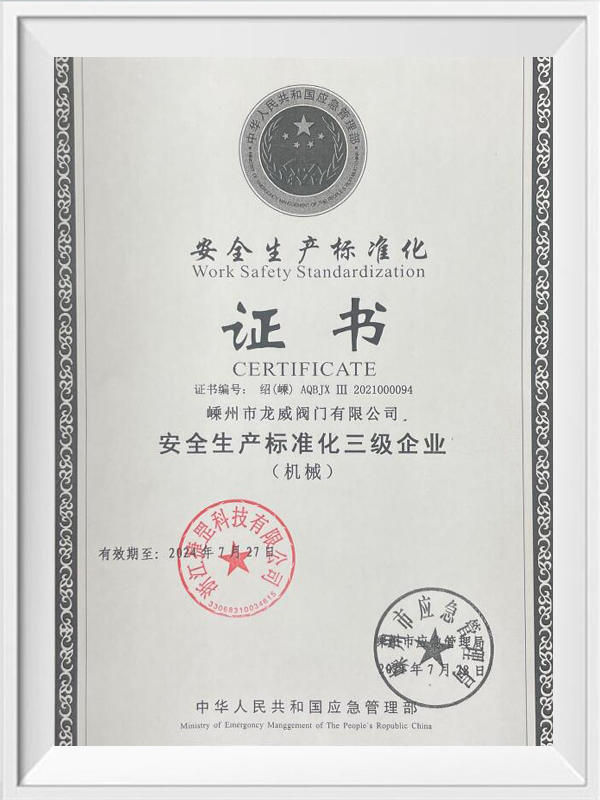

The company advocates the "one-to-one" design of "high efficiency and energy saving", that is, to make a special design according to the pulverization characteristics of the material, and strive for ultra-fine powder, minimize energy consumption, and stabilize equipment. The products are widely used in ultrafine grinding in different fields such as non-metallic minerals, chemical industry, medicine, biological food, rubber and plastics, fillers, building materials, pesticides, feed, batteries, new materials, new energy and environmental protection.

The company can develop and design products by itself according to the needs of users. It mainly includes superfine powder mill, air vortex micro powder mill, soft plastic and rubber crushing, vertical screenless, turbine crushing, etc. and a series of supporting equipment, crushing equipment classifier, conveyor, elevator, collector, dust collector Machine (pulse, simple), negative electrode material production line, graphite pulverizer, graphite shaping machine, graphite spheroidization equipment, plastic pulverizer, rice pulverizer, carbon black pulverizer, white carbon black pulverizer, PVA pulverizer, resin pulverizer machine, industrial salt crushing, white sugar crushing, calcium carbonate modification equipment, light calcium depolymerization equipment, nano-calcium depolymerization equipment, xanthan gum crushing equipment R&D, sales and production line projects.

In the field of lithium battery anodes, the crushing and shaping machines we have launched have been widely used in domestic similar mainstream enterprises, and have been widely used in raw material crushing, shaping, depolymerization of carbonized materials, wet granulation, pneumatic conveying and other fields. Shanghai Jiegang, the predecessor of Zhejiang Jiegang, has cooperated with the Sofia Institute to research and develop the natural graphite pulverization and spheroidization process since 2010. It has carried out the preliminary tests of the Yichang Hengda project and Jixi project based on the traditional multi-set series connection technology. Complete process test data. Since 2021, we have cooperated with the team of Professor Zhang Lingyan of Wuhan University of Technology to carry out the technical development of a new process of crushing and spheroidizing natural graphite. Starting from improving the use range and yield of natural flake graphite, we have developed special crushing and shaping technologies for natural flake graphite. Sincerely invite domestic and foreign customers to visit our factory, and look forward to your long-term cooperation to create a better tomorrow for you and me!

-

Annual Production Equipment

0+ -

Development Period

0+ -

Industry Development Years

0+ -

Plant Area

0㎡+

From The Blog

Provide you with the latest enterprise and industry news

-

Innovative Grinding Technology: Introduction of Carrageenan/Guar Gum Grinding Equipment

In the chemical, food and pharmaceutical industries, Carrageenan and Guar Gum are important natural polymer compounds, and their grinding and processi...

Read More >>> 2024-05-17 -

Carrageenan/Guar Gum Grinding EquipmentKey Technologies for Uniformity and Fineness

In the chemical, food and pharmaceutical industries that pursue high product quality, the grinding process of Carrageenan/Guar Gum Grinding Equipment ...

Read More >>> 2024-05-10 -

How does the nano calcium deagglomeration machine improve plant nutrient absorption efficiency in agricultural production?

The application of nano calcium deagglomeration machine in agricultural production has shown its potential, especially in improving the efficiency of ...

Read More >>> 2024-04-26 -

How does the calcium carbonate modification machine achieve particle size control?

The calcium carbonate modification machine involves a variety of processes and technical means to achieve particle size control, including mechanical ...

Read More >>> 2024-04-19

Industry Knowledge Extension

Next-Generation Coating Technology: The Advantages of Fusion Coating Machines

Contact Us

-

Email: [email protected]

-

Telephone: +86-17717510892

-

Fax:

-

Phone: +86-576-87685299

English

English عربى

عربى 한국어

한국어 中文简体

中文简体