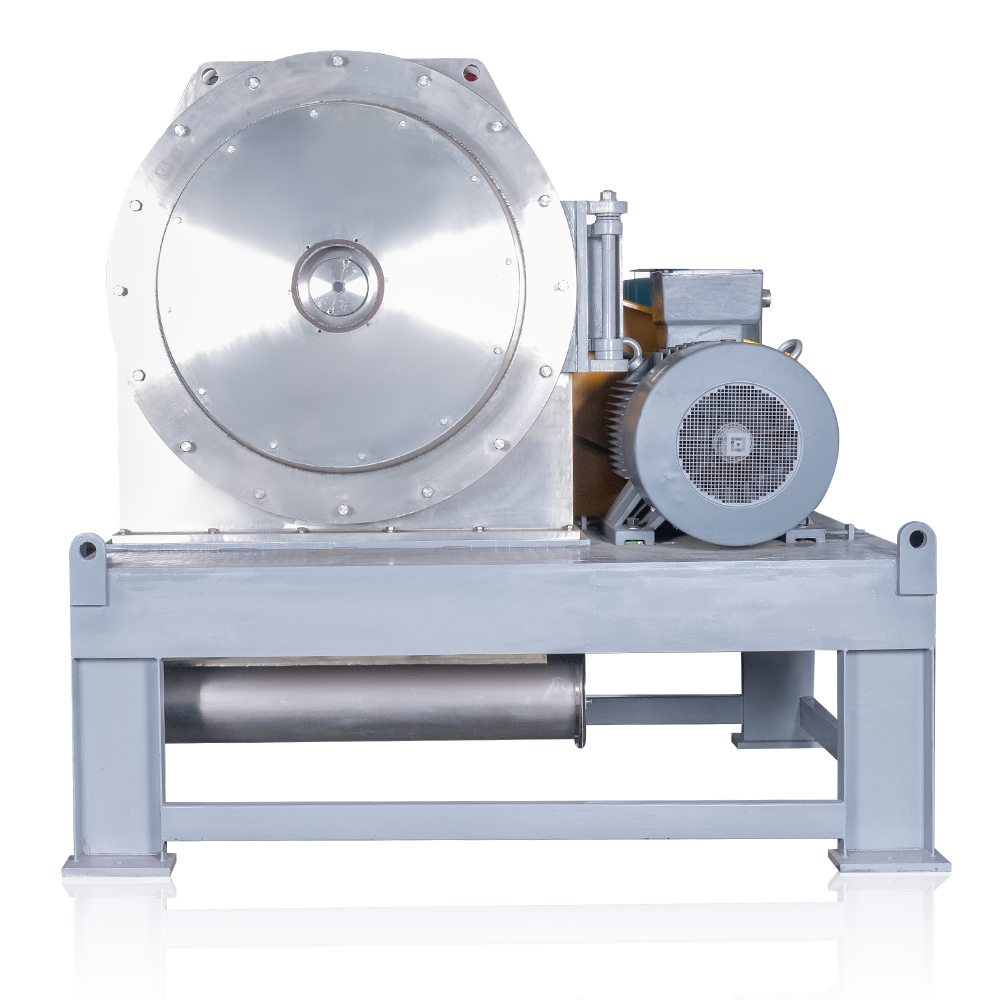

What are the characteristics of the pulverizer structure of carbon black crushing equipment?

The pulverizer structure of carbon black crushing equipment is the core component of the equipment, which directly affects the crushing efficiency, crushing quality and scope of application of the equipment. Understanding the characteristics of the crusher structure can help users better choose equipment suitable for their production needs and understand its working principle. The following are some main features of the pulverizer structure of carbon black crushing equipment:

Blade or hammer design: The pulverizer of carbon black crushing equipment is usually equipped with blades or hammers for crushing raw materials. The design of these blades or hammers affects the efficiency and quality of crushing. Generally speaking, the design of the blade or hammer head should be reasonable, which can not only provide sufficient impact and shear force, but also ensure wear resistance and strength.

Crushing chamber structure: The crushing chamber is the space inside the crusher, which is used to accommodate the raw materials and blades (or hammer heads) and carry out the crushing process. The structure of the crushing chamber should be reasonable to ensure that the raw materials can be fully impacted and sheared by the blade or hammer, and that the size and distribution of the particles can be effectively controlled.

The arrangement of the blade or hammer head: The arrangement of the blade or hammer head has an important impact on the crushing effect. Generally speaking, the arrangement of blades or hammers should be uniform to ensure that the raw materials are evenly impacted and sheared to avoid uneven particle size distribution.

Screen or grinding plate design: During the crushing process, some smaller particles may be discharged through the pores of the screen or grinding plate, while larger particles will continue to be crushed in the crushing chamber. Therefore, the design of the screen or grinding plate should be reasonable to ensure that the required crushing particle size can be met.

Adjustment device: The crusher is usually equipped with an adjustment device to adjust the rotation speed and movement trajectory of the blade or hammer to control the particle size and output during the crushing process. The adjustment device can adapt the equipment to different production needs and raw material characteristics, improving the flexibility and applicability of the equipment.

Wear-resistant materials and protective devices: Considering that the crusher may be subject to large impact and wear during the crushing process, the key components of the crusher are usually made of wear-resistant materials to improve its durability and service life. In addition, pulverizers are often equipped with guards to protect the safety of the operator.

Multifunctional design: Some high-end carbon black crushing equipment also has multifunctional design, which can crush different types of raw materials to meet the different processing needs of users. This design can improve the flexibility and scope of application of the equipment and provide users with more choices.

Blade or hammer design: The pulverizer of carbon black crushing equipment is usually equipped with blades or hammers for crushing raw materials. The design of these blades or hammers affects the efficiency and quality of crushing. Generally speaking, the design of the blade or hammer head should be reasonable, which can not only provide sufficient impact and shear force, but also ensure wear resistance and strength.

Crushing chamber structure: The crushing chamber is the space inside the crusher, which is used to accommodate the raw materials and blades (or hammer heads) and carry out the crushing process. The structure of the crushing chamber should be reasonable to ensure that the raw materials can be fully impacted and sheared by the blade or hammer, and that the size and distribution of the particles can be effectively controlled.

The arrangement of the blade or hammer head: The arrangement of the blade or hammer head has an important impact on the crushing effect. Generally speaking, the arrangement of blades or hammers should be uniform to ensure that the raw materials are evenly impacted and sheared to avoid uneven particle size distribution.

Screen or grinding plate design: During the crushing process, some smaller particles may be discharged through the pores of the screen or grinding plate, while larger particles will continue to be crushed in the crushing chamber. Therefore, the design of the screen or grinding plate should be reasonable to ensure that the required crushing particle size can be met.

Adjustment device: The crusher is usually equipped with an adjustment device to adjust the rotation speed and movement trajectory of the blade or hammer to control the particle size and output during the crushing process. The adjustment device can adapt the equipment to different production needs and raw material characteristics, improving the flexibility and applicability of the equipment.

Wear-resistant materials and protective devices: Considering that the crusher may be subject to large impact and wear during the crushing process, the key components of the crusher are usually made of wear-resistant materials to improve its durability and service life. In addition, pulverizers are often equipped with guards to protect the safety of the operator.

Multifunctional design: Some high-end carbon black crushing equipment also has multifunctional design, which can crush different types of raw materials to meet the different processing needs of users. This design can improve the flexibility and scope of application of the equipment and provide users with more choices.

Contact Us

-

Email: [email protected]

-

Telephone: +86-576-87685299

-

Fax: 0575-83505616

-

Phone: +86-17717510892

English

English عربى

عربى 한국어

한국어 中文简体

中文简体