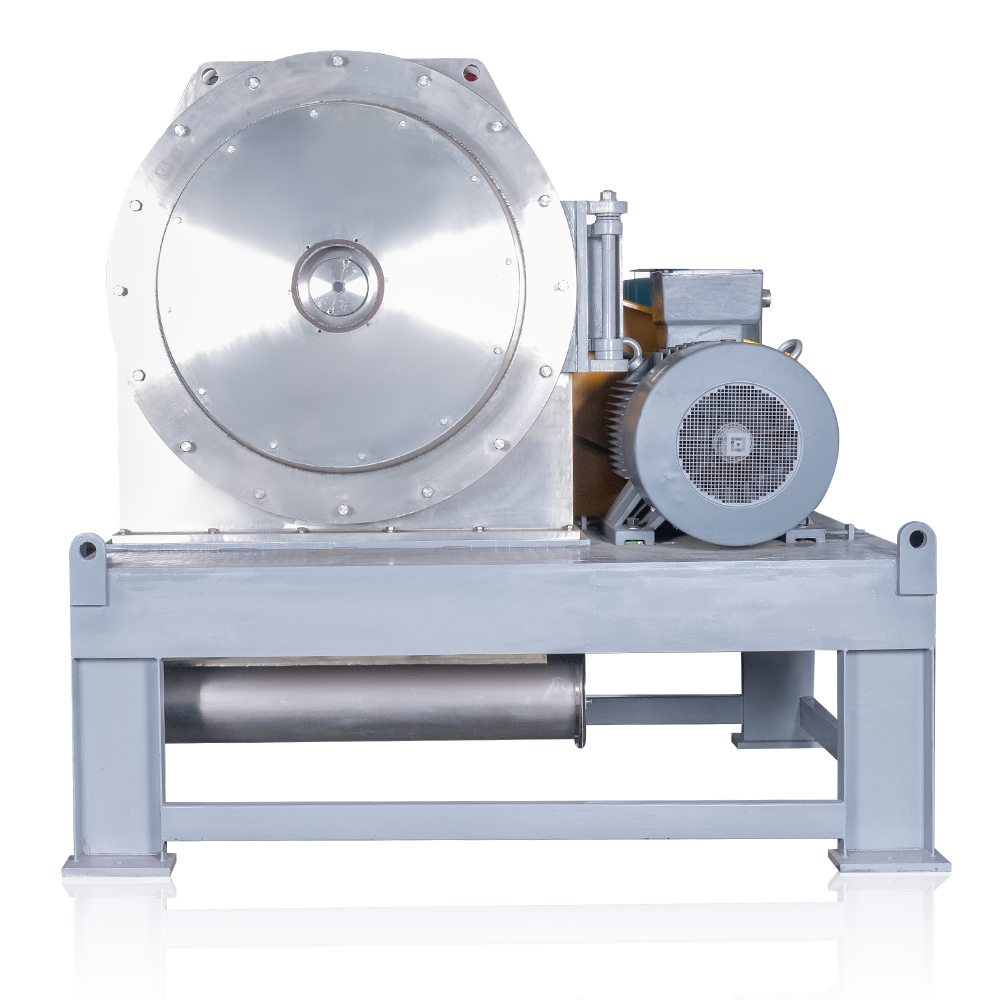

How does the efficient design and excellent performance of JKTM-1000 Cyclone mill meet the diverse needs of modern industrial production?

1. Efficient crushing design

The JKTM-1000 Cyclone mill adopts advanced conical rotor and stator design. By precisely adjusting the gap between the rotor and stator, it can effectively control the crushing fineness and output, improve the crushing efficiency, and ensure the uniformity and consistency of the crushing process. The conical structure of the rotor and stator allows the material to fully contact during the crushing process to achieve efficient crushing.

2. Application of high-strength materials

The rotor adopts special European high-strength steel, has extremely high linear speed, and can fully and evenly crush the material. The use of high-strength steel improves the durability and stability of the rotor and ensures safe operation at high linear speeds. The application of this material enables the JKTM-1000 Cyclone mill to cope with a variety of complex and high-hardness materials and meet the crushing needs of different industries.

3. Large processing air volume and low temperature rise

JKTM-1000 Cyclone mill has a very large processing air volume, which can maintain a low temperature rise during the pulverization process. It is particularly suitable for the processing of thermoplastic and fibrous materials, avoiding softening, melting or structural damage of materials caused by high temperature. Large processing air volume improves pulverization efficiency, ensures the temperature stability of materials during the pulverization process, and guarantees the quality and performance of the final product.

4. Horizontal design for easy maintenance and cleaning

JKTM-1000 Cyclone mill adopts a horizontal design, which makes the maintenance, operation and cleaning of the equipment more convenient. The horizontal design optimizes the structural layout of the equipment, improves the heat dissipation performance of the equipment, reduces the impact of temperature rise on the material, enables the equipment to maintain a stable working state during long-term operation, and reduces maintenance costs and operating difficulties.

5. Ultrafine pulverization equipment at the international advanced level

As a new generation of ultrafine pulverization equipment at the international advanced level, JKTM-1000 Cyclone mill has an advanced working principle and a unique adjustable gap function. The gap between the rotor and the stator can be adjusted without disassembling the machine, and the material stays in the pulverization area for a short time but is fully pulverized.

6. Motor and transmission system

JKTM-1000 Cyclone mill is equipped with high-performance motor and transmission system to ensure the stability and reliability of the equipment under high load operation. The motor adopts advanced cooling technology, which can maintain a low temperature rise during long-term operation and extend the service life of the equipment. The design of the transmission system makes power transmission more efficient, improves crushing efficiency and production quality.

7. Safety and environmental protection

JKTM-1000 Cyclone mill fully considers safety and environmental protection factors during the design process. The equipment adopts a closed structure to effectively prevent the leakage of dust and noise, and protect the health and working environment of the operator. The equipment is equipped with a variety of safety protection devices to ensure that it can be shut down in time under abnormal circumstances to avoid damage to equipment and personnel.

Contact Us

-

Email: [email protected]

-

Telephone: +86-576-87685299

-

Fax: 0575-83505616

-

Phone: +86-17717510892

English

English عربى

عربى 한국어

한국어 中文简体

中文简体