Why does the screen residue decrease with the increase of the classifying wheel speed?

1. Increased centrifugal force

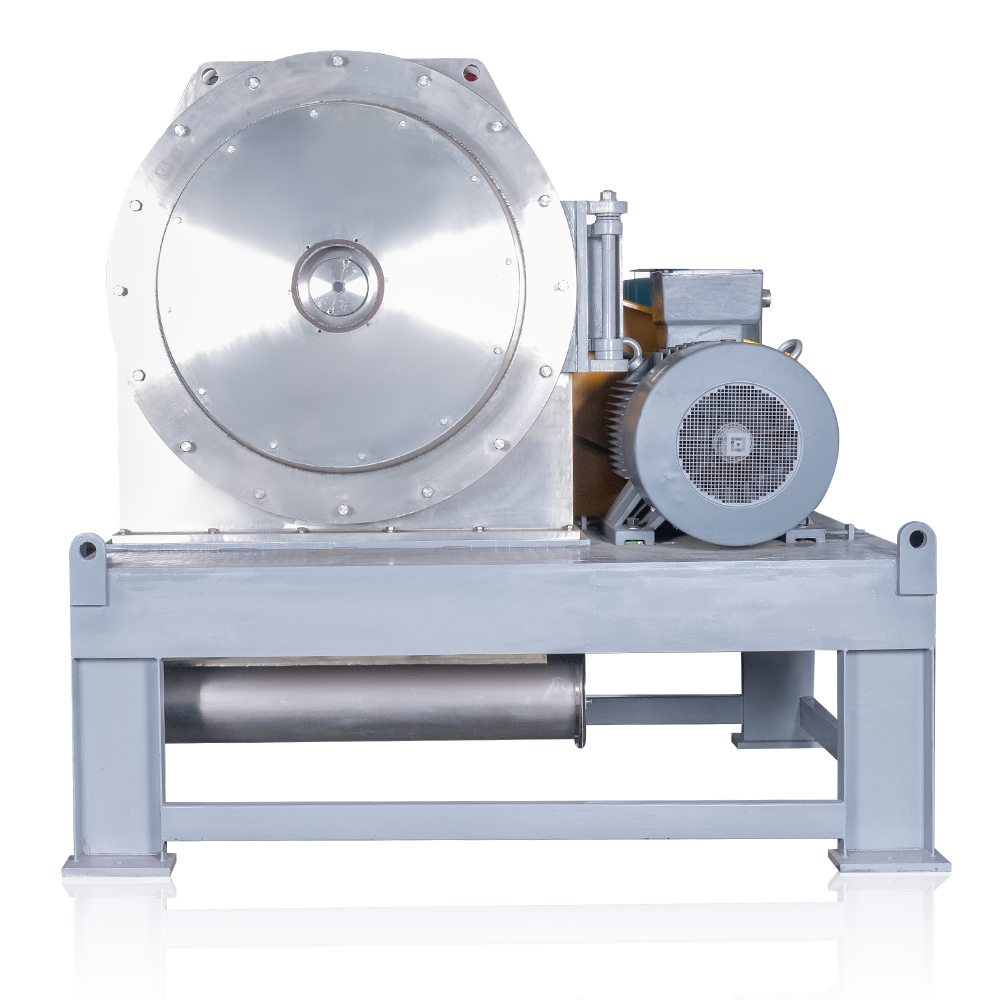

The speed of the classifying wheel directly affects the centrifugal force generated by the classifying impeller. In Carbon Black Crushing Equipment, the classifying impeller generates a strong centrifugal force by high-speed rotation to separate the fine powder and coarse powder in the material. When the speed of the classifying wheel increases, the centrifugal force increases accordingly. This enhanced centrifugal force makes it easier for the fine powder to be thrown out and enter the discharge pipe of the qualified product. The coarse powder with a larger mass is relatively less affected by the centrifugal force due to its large mass, and is left in the classification chamber to continue to be crushed until the required fineness is reached. As the speed increases, more fine powder is separated, and the screen residue naturally decreases.

2. Reduction of material residence time

The increase in speed will also affect the residence time of the material in the classification chamber. In Carbon Black Crushing Equipment, the longer the material stays in the classification chamber, the more opportunities it has to be crushed and classified. When the speed of the classifying wheel increases, the residence time of the material in the classification chamber will be reduced accordingly. Fine powder can be separated faster without staying in the classification chamber for too long. This rapid separation mechanism reduces the amount of screen residue because the fine powder can reach the separation standard and be discharged in a shorter time.

3. Enhanced shear force and impact force

The increase in the speed of the classifier wheel will also increase the shear force and impact force of the classifier impeller on the material. In Carbon Black Crushing Equipment, the classifier impeller plays the role of separating fine powder and coarse powder, and can also crush the material. When the speed of the classifier wheel increases, the shear force and impact force of the classifier impeller on the material will increase. This enhanced shear force and impact force make it easier for the material to be crushed into finer particles. The increase in fine powder directly leads to a reduction in the amount of screen residue because more material meets the fineness requirements.

Contact Us

-

Email: [email protected]

-

Telephone: +86-576-87685299

-

Fax: 0575-83505616

-

Phone: +86-17717510892

English

English عربى

عربى 한국어

한국어 中文简体

中文简体