How to achieve fineness and output control of JKTM-1000 Cyclone mill by adjusting the gap between the rotor and the stator?

Precision fit between rotor and stator

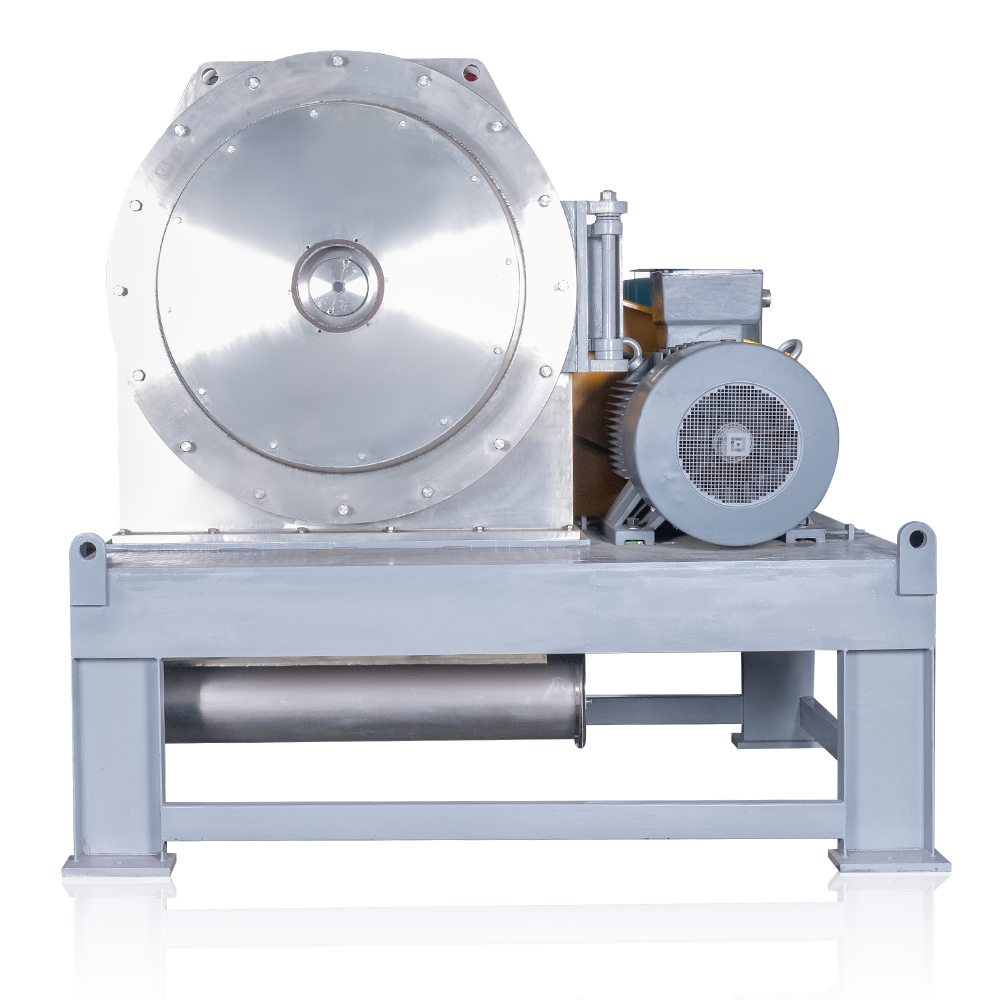

The core components of JKTM-1000 Cyclone mill are its conical rotor and stator. This design improves the crushing efficiency of the equipment and makes it possible to control fineness and output. The gap between the rotor and the stator is a key parameter that determines the material crushing effect. By accurately adjusting this gap, the fineness and output of the material can be accurately controlled.

Principle of fineness control

In JKTM-1000 Cyclone mill, the gap between the rotor and the stator directly affects the degree of material crushing. When the gap is small, the shear force and impact force of the material in the crushing chamber are greater, and it is crushed into finer particles. Conversely, when the gap is large, the shear force and impact force of the material are reduced, and the crushed particles are relatively large. By adjusting the gap between the rotor and the stator, the fineness of the material can be accurately controlled.

Output control principle

In addition to fineness, JKTM-1000 Cyclone mill can control output by adjusting the gap between the rotor and stator. When the gap is small, although the material is crushed finer, the amount of material passing through the crushing chamber is relatively small, and the output is low. When the gap is large, although the fineness of the material may be slightly inferior, the amount of material passing through the crushing chamber increases, and the output is correspondingly increased. Therefore, users can balance fineness and output by adjusting the gap according to production needs to achieve the best production effect.

Convenience of adjustment mechanism

The design of JKTM-1000 Cyclone mill fully considers the convenience of user operation. The gap between its rotor and stator can be adjusted by a simple mechanical device without disassembling the equipment, simplifying the operation process. This design improves the efficiency of equipment use, reduces maintenance costs, and enables users to respond to different production needs more flexibly.

Contact Us

-

Email: [email protected]

-

Telephone: +86-576-87685299

-

Fax: 0575-83505616

-

Phone: +86-17717510892

English

English عربى

عربى 한국어

한국어 中文简体

中文简体