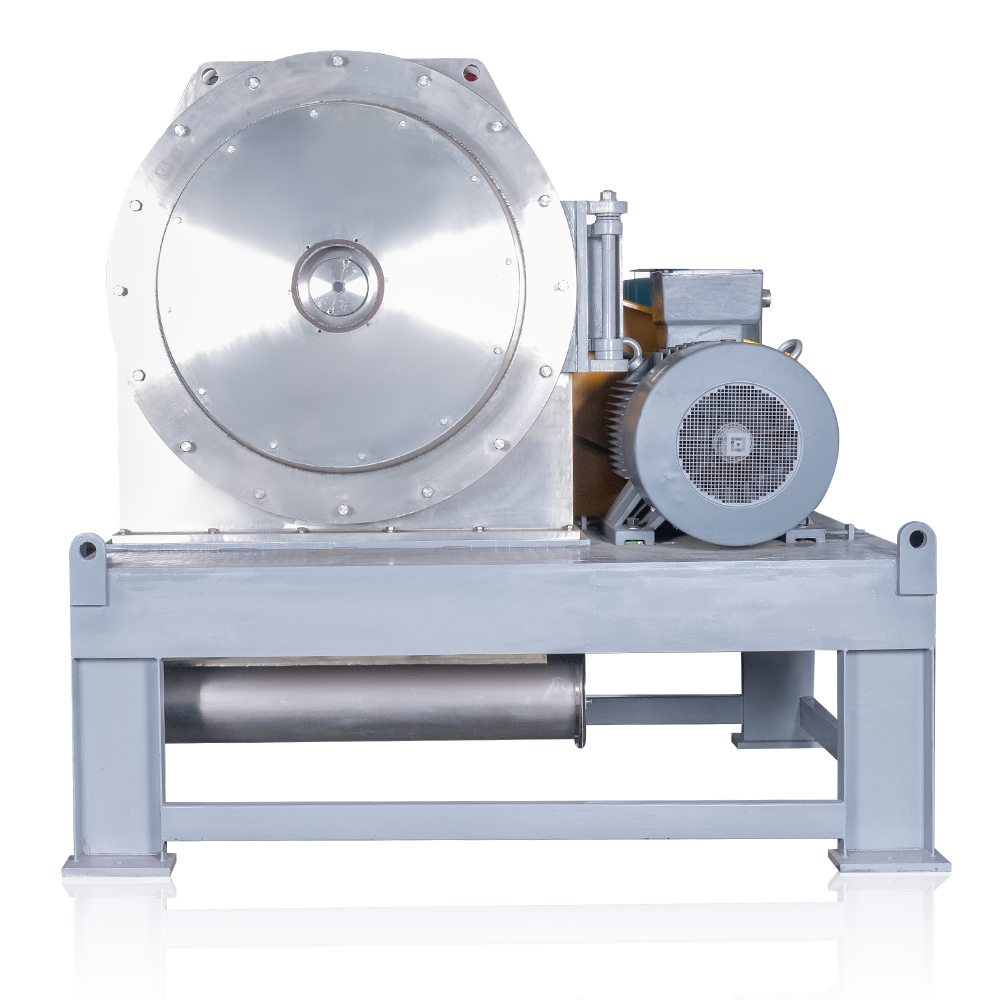

How to use Air Flow Mill Mechanical Grinding Roller Pressure Grinding Three-in-One Test Machine for grinding and testing chemical raw materials?

Equipment Introduction

Air Flow Mill Mechanical Grinding Roller Pressure Grinding Three-in-One Test Machine is a multifunctional testing equipment that integrates air grinding, mechanical grinding and roller grinding. Designed for laboratory and small production environments, this equipment is suitable for fine grinding and testing of various materials, such as powders, granules, fibers, etc. Its unique three-in-one design improves grinding efficiency and ensures the accuracy and consistency of the grinding process.

Equipment Operation Steps

1. Preparation Phase

Before grinding and testing chemical raw materials, you first need to ensure that the equipment is in good working condition. Check whether the various parts of the Air Flow Mill Mechanical Grinding Roller Pressure Grinding Three-in-One Test Machine are intact and ensure that the power and air sources are connected normally. Select the appropriate grinding method (air grinding, mechanical grinding or roller grinding) according to the characteristics of the chemical raw materials to be ground.

2. Parameter Setting

Set the grinding parameters through the touch screen control panel of the equipment. These parameters include grinding time, grinding speed, grinding pressure, etc. According to the characteristics of the chemical raw materials, these parameters are set accurately to ensure the accuracy and consistency of the grinding process. After setting the parameters, the grinding process can be monitored in real time through the control panel to ensure the smooth progress of the grinding process.

3. Grinding process

Put the chemical raw materials to be ground into the feed port of the equipment and start the equipment. The equipment will grind according to the preset parameters. During the grinding process, the air mill, mechanical grinding and roller grinding devices of the equipment will work together to finely grind the chemical raw materials. The dust and exhaust gas generated during the grinding process will be discharged through the exhaust system of the equipment to ensure the cleanliness and safety of the working environment.

4. Result analysis

After the grinding is completed, the ground chemical raw materials are taken out for testing and analysis. By comparing the chemical raw materials before and after grinding, the grinding effect and the grinding performance of the equipment can be evaluated. According to the test results, the grinding parameters can be optimized to improve the grinding effect.

Equipment Advantages

1. Versatility

The Air Flow Mill Mechanical Grinding Roller Pressure Grinding Three-in-One Test Machine integrates air grinding, mechanical grinding and roller grinding, and can meet the testing of different chemical raw materials and different grinding needs. Whether it is powder, granules or fibers, the equipment can perform fine grinding to meet the grinding needs of various chemical raw materials.

2. High precision

The equipment adopts advanced control systems and precision grinding components to ensure the accuracy and consistency of the grinding process. The grinding particle size can be precisely controlled to meet the strict requirements of chemical raw materials for particle size.

3. High efficiency

The three-in-one design improves grinding efficiency, shortens grinding time and improves production efficiency. Whether it is laboratory testing or small-scale production, the equipment can provide efficient and stable grinding services.

4. Easy to operate

The equipment is easy to operate, and the grinding parameters can be easily set through the touch screen control panel to monitor the grinding process in real time. Even non-professionals can quickly master the operation method of the equipment to grind and test chemical raw materials.

5. Safety

The equipment has multiple safety protection measures, such as overload protection, temperature protection, etc., to ensure the safety of operators and equipment. During the grinding process, the exhaust system of the equipment will discharge dust and exhaust gas to ensure a clean and safe working environment.

Contact Us

-

Email: [email protected]

-

Telephone: +86-576-87685299

-

Fax: 0575-83505616

-

Phone: +86-17717510892

English

English عربى

عربى 한국어

한국어 中文简体

中文简体