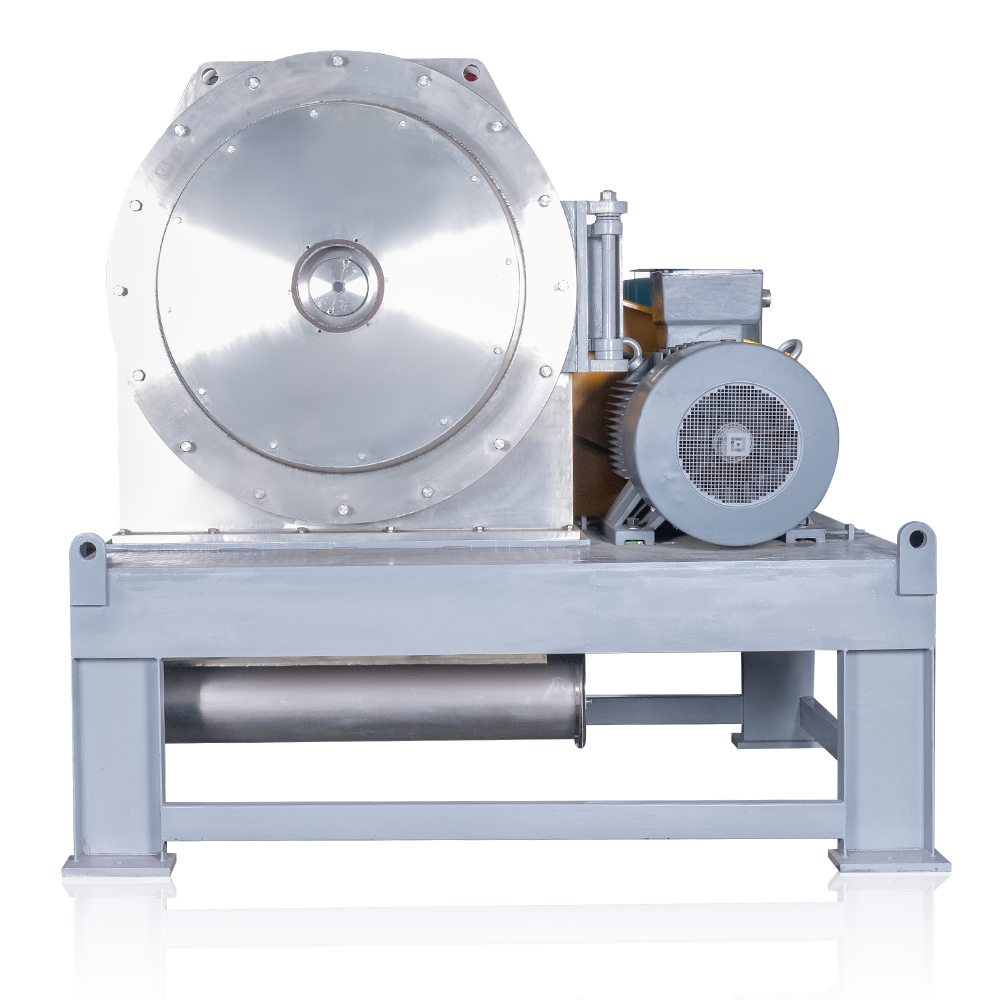

Why does the Turbo Ultrafine Classifier need to be equipped with a secondary classifier and a secondary air intake device?

1. Improve classification accuracy and efficiency

Turbo Ultrafine Classifier can further improve classification accuracy through the cooperation of secondary classifier and secondary air intake device. During the initial classification process, the material is separated into coarse and fine particles by the classification wheel, but some fine powder may carry a small amount of coarse particles. These coarse particles re-enter the classification area under the action of the secondary air intake device and are separated again to achieve a finer classification effect.

2. Optimize particle size distribution

Turbo Ultrafine Classifier can effectively control the particle size distribution through the secondary classifier to ensure uniform particle size of the final product. By adjusting the secondary air intake volume and the speed of the classification wheel, the particle size can be accurately controlled, so that the particle size range is between 3~150 μm, and even more than 97% of the ultrafine powder with a mass fraction of less than 5 μm.

3. Reduce coarse particle entrainment

Since coarse particles may be entrained during the classification process, the introduction of secondary classifier and secondary air intake device can effectively reduce the contamination of coarse particles on fine powder and improve the purity and quality of fine powder.

4. Improve equipment performance and reliability

The sealing structure and secondary air intake design of Turbo Ultrafine Classifier make the equipment run more stably in high dust environment, reducing the possibility of material leakage and equipment wear. The introduction of the secondary air intake also provides stable aerodynamic support for the classification process, ensuring the efficiency and stability of equipment operation.

5. Adapt to different material requirements

Turbo Ultrafine Classifier can flexibly respond to the classification requirements of different materials and achieve precise control of particle size by adjusting the secondary air intake volume and the speed of the classification wheel. This flexibility enables Turbo Ultrafine Classifier to be widely used in chemical, pharmaceutical, non-metallic mineral and other industries to meet the requirements of different particle size specifications.

6. Reduce energy consumption and improve production efficiency

The secondary sorting and secondary air intake technology of Turbo Ultrafine Classifier improves classification efficiency and reduces energy consumption. By optimizing airflow distribution and classification parameters, the equipment can achieve continuous production, reduce downtime and improve overall production efficiency.

Contact Us

-

Email: [email protected]

-

Telephone: +86-576-87685299

-

Fax: 0575-83505616

-

Phone: +86-17717510892

English

English عربى

عربى 한국어

한국어 中文简体

中文简体